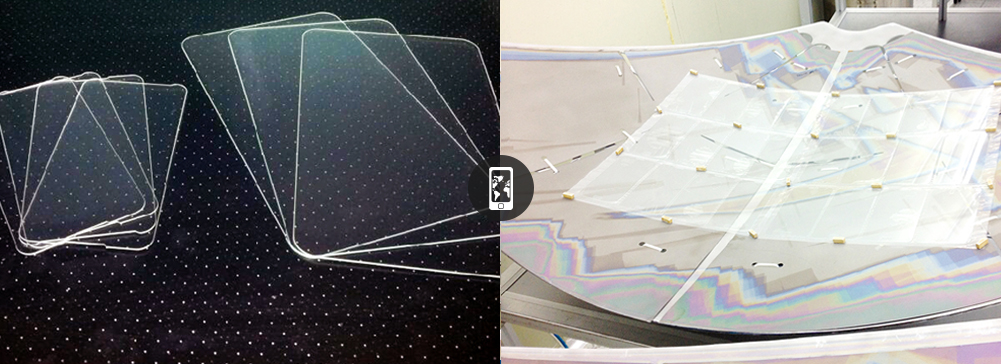

Glass surface needs to be protected during cover glass manufacturing processes. Some applications like AF coating process require heat resistance performance in high temperature environment. The most important point is the film should not make any residue on the sensitive glass surface.

Protect glass surface without any residue and smudge problem

Protect glass surface without any residue and smudge problem

G20, G17 for full coverage of glass process

G20, G17 for full coverage of glass process

Low adhesion G05,G10 for inter-process protection

Low adhesion G05,G10 for inter-process protection

GP-20 for extreme temperature environment(over 150℃ ) usage

GP-20 for extreme temperature environment(over 150℃ ) usage

| Item | Film | Adhesive | Peel force(gf/25mm) |

Thickness(µm) |

Applications |

|---|---|---|---|---|---|

G20 |

PE |

Acrylic |

30 ± 7 |

80 | ·Heat resistant PE protection tape. Used for AF coating. ·Can be used for all the glass processes. |

20 ± 5 |

50 | ·Thin G20. Low price ·Protection for inter-processes and ex-factory glass packing |

|||

25 ± 5 |

150 | ·For high temperature and short period process |

|||

G17 |

PE |

Acrylic |

15 ± 5 |

50, 80 |

·Soft peel-off with heat resistance. ·Used for AF coating on glass process |

G10 |

PE |

Acrylic |

10 ± 3 |

50, 80 |

·Protection for inter-processes and ex-factory glass packing |

| G05 | PE | Acrylic | 7 ± 3 |

50, 80 |

·Low adhesion. Easy for use. ·Used for repeated lamination and peel-off |

G05B |

BLUE PE |

Acrylic |

7 ± 3 |

80 |

·Low adhesion. Easy for use. ·Used for indication of processing surface |

G50 |

PE |

Acrylic |

50 ± 10 |

80 |

·High adhesion usage. ·Used for AF coating on glass process |

GP20 |

PET |

Acrylic |

10 ± 3 |

50, 75 |

·Suitable to the extreme temperature of AF coating, IR drying process. ·Can be used for 150℃ environment |